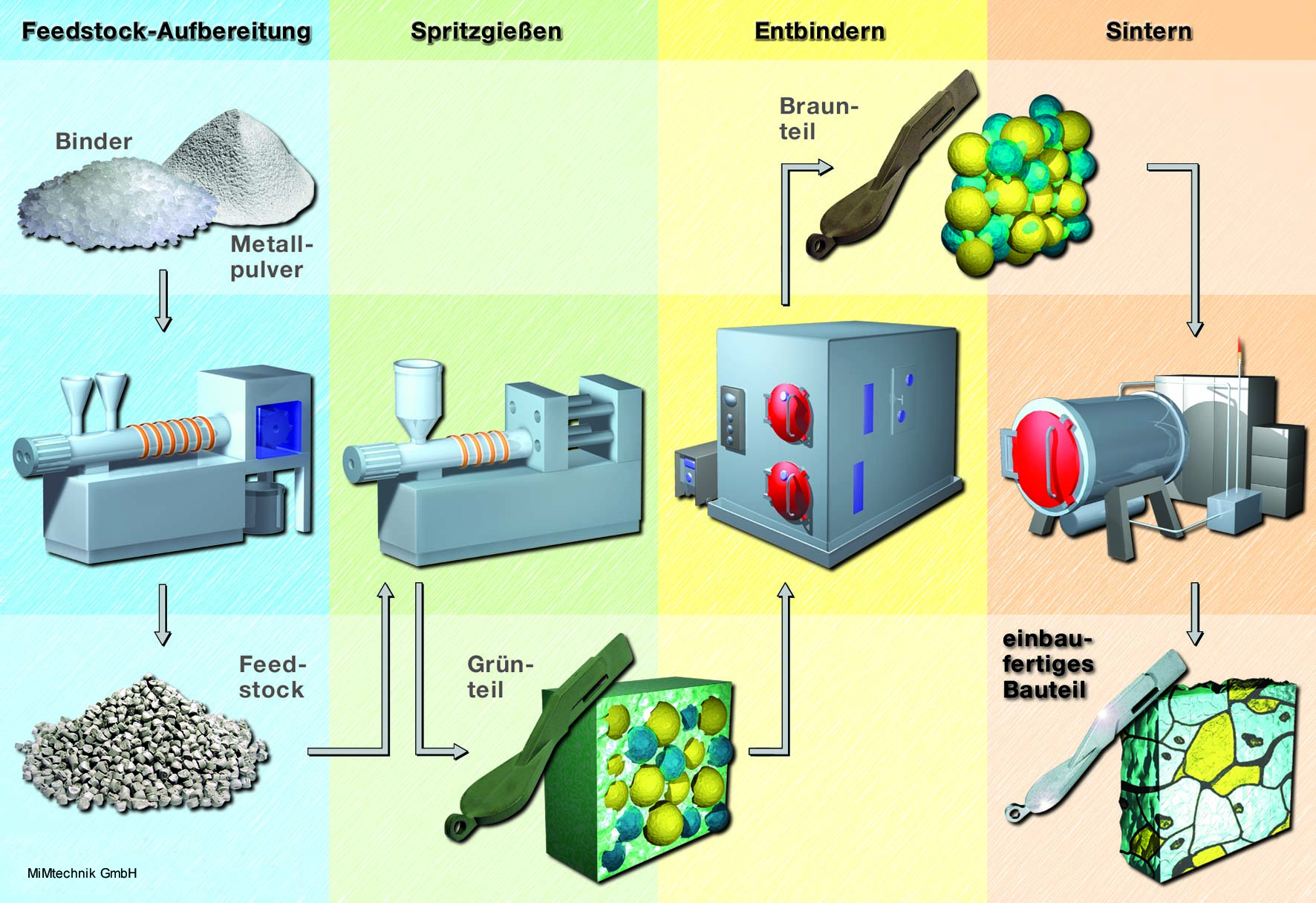

MIM - Metal Injection Molding

MIM - metal powder injection moulding offers a wide range of design possibilities. A major advantage of this process is that components with demanding geometries, which can only be produced in multiple parts using conventional methods, can be manufactured in a single piece.

Available Materials

Steel - Titanium - Cu alloys - Silver - Gold

Typical Component Sizes

- Weight from 1.0 gr to approx. 100 gr / heavier parts also possible

Sizes: 5 mm - ca 100 mm

Quantities: starting from 1000 pcs per lot

Production Examples |

||

|

|

|

| Impact lever for Pistol Material MIM-FeNi8 Weight 19.9 g L= 38 mm |

Gear with shaft Material 16MnCr5 Weight 10.0 g Ø 18.0 mm |

Shutter block for Pistol Material MIM-16MnCr5 Weight 31.85 g L= 53 mm |

|

|

|

| Drive - fine adjustment for Binoculars Material MIM-316L, Weight 5.81 g, L = 17 mm |

Lock Part "Nut" Material 1.4542 Weight ca 12 gr Wall Thickness 2,6 mm |

Door Latch Material 1.4542 Weight ca 19 g Length 32 mm |

MIM - Method

Applications

| Application Fields | |

|---|---|

| Microtechnology: | Housing / Micro-Precision Parts |

| Automotive: | Transmission parts / Functional components |

| Medical: | Chir. Tools / Arthroscopy Instruments |

| Optical Industry: | Parts for Cameras and Laser Systems |

| Consumer Electronics: | Drive parts for CD players |

| Electrical Industry: | Device connectors, Contacts, Magnetic Applications |

| Textile Machinery Industry: | Components for embroidery and Sewing Machines |

| Fitting and Lock Industry: | Parts for Micro-Locks and Visible Parts |

| Watch Industry: | Watch cases, bracelets, gears |

| Jewelry industry: | Chains, Pendants, Rings |

| Gun Components: | Whip, Lock Block |

Tolerances

Achievable Tolerances and Surfaces Finishes

Nominal Dimension (mm)

| < | 3 | 0.05 | ||||

| 3 | - | 6 | 0,06 | |||

| 6 | - | 15 | 0,075 | mm | ||

| 15 | - | 30 | 0,15 | mm | ||

| 30 | - | 60 | 0,25 | mm | ||

| > | 60 | 0,5 % | of the nominal dimension |

Tolerances for MIM Precision

| < | 0,5% | of the measure of length | |

| Angle | +/- | 0° 30' |

Surface roughness MIM [micrometer]

| Rz | > | 4 | - | 20 |

Typical component-Characteristics

| Dimension | 5,0 | mm | to | 10 | mm |

| Wall Thickness | 0,5 | mm | to | 3 | mm |

| Weight | 0,1 | g | to | 100 | g |

Materials

| Type | M.-No. | Short Description | Characteristics | Applications |

|---|---|---|---|---|

| Low Alloyed Steels | ||||

| Fes1 | - | FeC | Cabonyle Iron + C | Components with lower mech. characteristics |

| FN02 | - | FeNi2 | Cabonyle Iron + Nickel | General components with a very good surface quality |

| FN02C | - | FeNi2+0.6C | Cabonyle Iron + Nickel + C | General components, hardenable |

| FN08 | - | FeNi8 | Cabonyle Iron + Nickel | General machine components requesting high ductility |

| FN08C | - | FeNi8+0.6C | Cabonyle Iron + Nickel + C | General machine components, hardenable |

| Fe2Cu | - | FeCu2-5 | Cabonyle Iron + Cu | General machine components, higher strengths than FeNi basic materials |

| 42CrMo4 | 1.7225 | 42CrMo4 | Tempering steel, parts with high strength and toughness, large compensation gauge | Gears, Shafts, Automotive parts |

| 21NiCrMo2 | 1.6523 | 21NiCrMo2 | Case-hardening steel, parts subject to extreme stress, cold forming | Disc wheels, Camshafts |

| Stainless and acid resistant steels | ||||

| 316L | 1.4404 / 1.4435 | 316L / VA4 | austenitic, nonmagnetizable, good corrosion resistance. low hardness, high toughness | Watches & Jewelery, medical instruments, polished parts, general equipment , chem. Industry. |

| 17-4PH | 1.4542/ 1.4548 | 17-4PH | nonmartensitic, ferromagnetic, corrosion-resistant. can be hardened by precipitation hardening | Pump parts, medical parts, automotive parts, machine components, aviation and marine parts |

| X15CrNiSi25.20 | 1.4841 | X15CrNiSi25.20 | heat resistant up to 1150 ° C | Catalyzers, industrial furnaces |

| X12CrNiMoNb20.15 | 1.4885 | X12CrNiMoNb20.15 | heat resistant up to 1000 ° C | Brackets of blank annealing furnace, industrial furnace parts |

| 420 | 1.4021 | X20Cr13 | martensitic, ferromagnetic, low corrosion resistance, high hardness, can be tempered | Pump parts, medical engineering parts, turbine blades, knives, cutting parts |

| 430 | 1.4016 | X6Cr17 | martensitic, ferromagnetic, corrosion resistant | for ferromagnetic, stainless components, cutlery, automotive parts |

| Tool Steels | ||||

| M2 | 1.3343/ 1.3342 | S-6-5-2 | High-Speed Steel | Reamers, Spiral Drills, Drills, Taps, Countersinks, Precision Tools |

| 100Cr6 | 1.2067 | - | Alloyed High-Speed Steel, high hardness and wear resistance | Gauges, mandrels, punches, woodworking tools, flanging rollers, drawing mandrels |

| Steels with spec phys properties | ||||

| FeN | FeN | carbon-free carbonyl iron, magnetizable | magnetic components | |

| FeSi3 | 1.0884 | FeSi3 | high saturation magnetization | |

| FeCo | FeCo48 | very high saturation magnetization | magnetic components | |

| FeCoV | FeCo49V2 | very high saturation magnetization | ||

| Kovar | Kovar | Magnetic material | magnetic components | |

| Invar | 1.3912 | Invar | Expansion alloy, smallest thermal expansion | bimetallic |

| Copper Base Materials | ||||

| Cu | Cu | pure Copper | Electrical engineering, contacts | |

| CuNixx | CuNi3-30 | Coin alloy, plating material, contacts | ||

| CuNiH | CuNiH | high hardness | Electrical engineering, contacts, fittings, tribological properties | |

| CuFe | CuFe | average hardness | Electrical engineering, contacts, fittings, tribological properties | |

| Heavy Metals | ||||

| WNiFe/A | WNi4Fe3 | shields radioactive radiation | Medical technology, sensor technology | |

| WCu10/A | WCu10 | excellent burn-off resistance | Electrical engineering, contacts | |

| WCu20/A | WCu20 | excellent burn-off resistance | Electrical engineering, contacts | |

| Carbides | ||||

| WCCo6 | WCCo6 | Medical technology | ||

| WCCo10 | WCCo10 | Cutters, hard metal moldings and components | ||

| Light Metals | ||||

| Ti / B | 3.7065 | Ti ( Grad4) | ASTM Grade 4, non-magnetizable, high corrosion resistance, light | Watches, jewelery, medical technology, food technology, aviation |